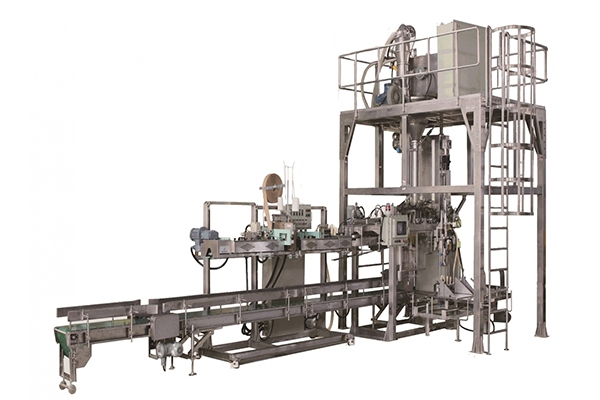

Packaging Equipment

Ultra-fine powder automatic filling packaging machine

- Product ID:

- Size:

- Material Science:

- INQUIRY

Bottom-filling packaging machines are used to package ultra-fine powder materials such as chemicals and building materials. During the process, this is done with no dust improving the working environment of the workshop. It can automatically complete material degassing, lifting bag bottom filling, metering and sealing, and conveying. Developed and designed for ultra-fine powders that are prone to dust and high-precision packaging requirements, it is particularly suitable for high-precision packaging of ultra-fine powders such as pharmaceutical raw materials, additives, cobalt tetroxide, carbon powder, and fire extinguisher dry powder.

Main features

1. Vertical spiral feeding makes feeding more uniform and stable. The screw cut-off valve ensures packaging accuracy.

2. The silo and quick-release screw assembly can be opened to make cleaning of equipment that contacts with the material simple and fast.

3. Lifting bottom filling metering, combined with screw vacuum degassing, ensures that there is no dust.

Main performance and technical parameters

Single-station lifting filling

Maximum packaging capacity 40-100 bags/hour

Filling volume 20-50 kg

Bag size 550-1050/width-length

Air source 0.5-0.7Mpa

Equipment power 5.0 kW

PRODUCTS

News

Contact Us

Contact: Venka Industrial Technology

Phone: +86 13663827325

Tel: +86 13663827325

E-mail:

Add: High Technology Area, Zhengzhou, Henan, China